Does a Loading Dock Ramp Call For Bed Rails?

Introduction

Loading dock ramps play a essential role in the reliable functioning of warehouses, warehouse, and manufacturing facilities. These ramps supply a smooth transition for the movement of products in between vehicles and the loading dock, enhancing the loading and dumping procedure. One common question that develops in the style and installment of loading dock ramps is whether they call for rails. In this article, we will check out the value of dock ramps, the function of imprison their style, and the aspects to take into consideration when determining whether a loading dock ramp calls for rails.

The Functionality of Loading Dock Ramps

Loading dock ramps, often referred to as dock loading ramps, serve as a bridge in between the elevation of a vehicle bed and the elevation of a loading dock. They promote the smooth and secure motion of products, equipment, and vehicles. These ramps are crucial for maximizing the logistics and transportation processes in numerous markets.

Importance of Dock Loading Ramps

Reliable Loading and Unloading: Dock loading ramps allow the seamless transfer of items between vehicles and the loading dock. This performance is vital for reducing downtime and ensuring a constant circulation of products in and out of the facility.

Convenience: Loading dock ramps fit various kinds of lorries and equipment, making them flexible for a wide variety of applications. Whether it's a forklift, pallet jack, or handcart, these ramps supply a global service for packing and dumping.

Security: Properly created and mounted loading dock ramps enhance security by minimizing the threat of accidents during the loading and unloading process. They supply a secure surface area for employees and tools, preventing slips, trips, and falls.

The Role of Rails in Loading Dock Ramp Design

Rails, or guardrails, are a common feature in loading dock ramp design. They serve numerous objectives, adding to both safety and security and capability. Below are some crucial functions of rails in loading dock ramp design:

Loss Protection: Rails work as a obstacle, stopping personnel, equipment, or products from inadvertently falling off the sides of the ramp. This is especially crucial when managing elevated platforms and differing heights in between trucks and filling docks.

Guidance for Equipment: Rails give assistance for equipment such as forklifts, making sure a straight and protected course during the loading and dumping process. This aids in avoiding unintended collisions and damages to both the ramp and the equipment.

Compliance with Regulations: Depending on neighborhood safety policies and building ordinance, the inclusion of guardrails on loading dock ramps may be a need. Conformity with these policies is important to stay clear of legal issues and guarantee a risk-free workplace.

Variables to Consider in Deciding Whether Rails are Necessary

While rails offer several advantages in loading dock ramp style, there are aspects to think about when determining whether they are essential for a details application:

Sort Of Material Handling Equipment: If the key tools made use of for packing and discharging is a forklift or other heavy machinery, rails may be a lot more important to avoid unintentional falls and provide advice. On the other hand, if the devices is lightweight and manoeuvrable, the requirement for rails may be lowered.

Frequency and Volume of Traffic: Facilities with high website traffic quantity and frequent use loading dock ramps might benefit more from the incorporation of guardrails. They give an additional layer of protection in hectic environments where the threat of mishaps is greater.

Expense Considerations: While safety must be a top priority, price considerations can not be overlooked. The addition of rails may raise the overall expense of the loading dock ramp task. Evaluating the spending plan and weighing the benefits versus the price is important in making an notified choice.

Verdict

In conclusion, the decision of whether a loading dock ramp needs rails relies on numerous factors, including the sort of equipment utilized, the regularity of use, and conformity with safety policies. While rails contribute substantially to safety and security and capability, each application is one-of-a-kind, and a mindful analysis of details demands is crucial. Loading dock ramps, with or without rails, play a pivotal duty in maximizing product dealing with processes and ensuring the smooth procedure of stockrooms and distribution centers. Ultimately, a properly designed loading dock ramp, whether outfitted with rails or not, enhances performance, security, and total efficiency in the logistics and supply chain industry.

Web:https://www.chinaniuli.com

E-mail:niuli_jason@chinaniuli.com dock ramp

Tel/Whatsapp:+86 dock loading ramps 13427190577

Skype:kukushy1314 dock loading ramps

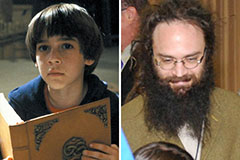

Barret Oliver Then & Now!

Barret Oliver Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Heather Locklear Then & Now!

Heather Locklear Then & Now!